Services

Explore all our NDT services offering.

Expertly crafted by our skilled team

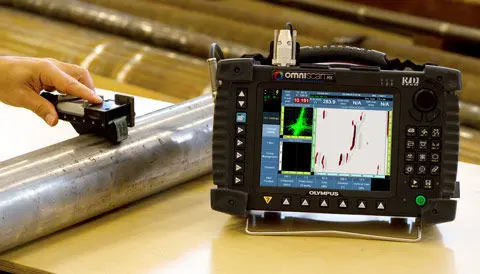

🔹Phased Array Ultrasonic Testing (PAUT)

Advanced UT technique using multiple elements to inspect welds and complex geometries with high precision and faster scanning.

🔹 Ultrasonic Testing (UT)

Uses high-frequency sound waves to detect internal flaws in welds, castings, and materials without causing any damage.

🔹 The Internal Rotary Inspection System (IRIS)

Specialized for inspecting corrosion and wall loss in heat exchanger tubes using rotating ultrasonic sensors.

🔹 Post Weld Heat Treatment (PWHT)

Controlled heating and cooling of welds to relieve residual stress, reduce hardness, and improve metallurgical properties.

🔹 Dye Penetrant Testing (DPT / LPT)

Effective surface crack detection using dye and developer – ideal for non-ferrous materials and smooth surfaces.

🔹 Metallography

Microscopic examination of material structure to identify grain size, phases, and defects for quality analysis and failure investigation.

🔹 Magnetic Particle Testing (MPT)

Detects surface and near-surface cracks in ferromagnetic materials using magnetic fields and iron particles.

🔹 Positive Material Identification (PMI)

On-site alloy verification using XRF or OES to ensure correct material composition before or after fabrication.

🔹 Ultrasonic Thickness Gauging (UTG)

Measures material thickness to monitor corrosion or erosion in pipes, tanks, and structural components.

Our Client